The Product Schedule component is used to create products on the conveyors listed in the Entry Components. If multiple entry conveyors are specified, the product schedule will create products on each conveyor round robin style (1, 2, 3, 1, 2, 3, 1 etc.). The Entry Components list can also have the equipments handled by other logical processor

Each product schedule as a Queue. When a product cannot be placed on the entry conveyor(s) because it is full, the product is placed in the queue. Once the product is in the queue, it will be inserted as soon as possible when a gap becomes available. It is possible to monitor the queue size in a report.

The property Max Queue Size allows you to limit the size of the queue to avoid infinite queues growing. If the queue as reached its maximum size, any product that should be created according to the schedule is discarded (not created), so the total amount of products created may not be equal to the amount specified in the product schedule. The default value for Max Queue Size is zero (no queue).

Example: a schedule creates 1 product every 5 seconds on 2 conveyors A and B. if both A and B are "free", 1 product will be created on each conveyor every 10 seconds. If A is occupied, the schedule will only create products on B every 5 seconds. If both A and B are busy, the queue will keep increasing (by 1 every 5 seconds) and will attempts to place products on A or B as soon as possible.

In System Time (queued) includes the time when the product was in the queue, whereas In System Time (Inducted) calculates the In System time of a product from the time it was first inducted in the system.

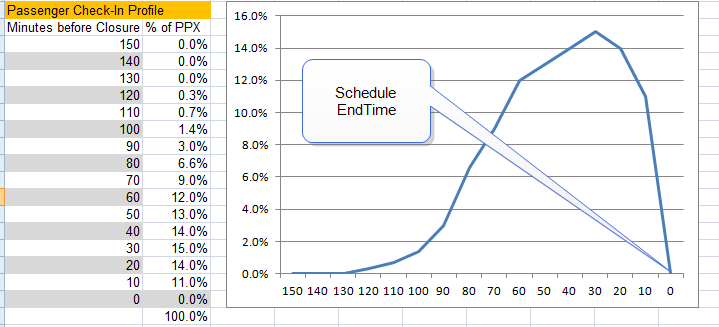

A product schedule has a start and an end time, they create the number of products between the start and end time.

If the queue is not empty at End Time, the product schedule will keep running to empty the queue after End time.

A list of Destinations can be configured. The destinations can then be used in Rules to determine which products are pushed. If several destinations are configured, they will be assigned to products round robin style (1, 2, 3, 1, 2, 3, 1, etc.).

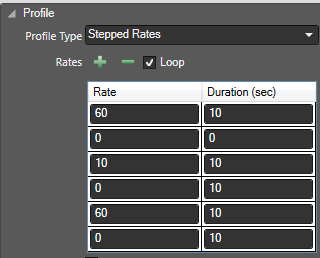

There are three types of Product Schedule:

Simply drag and drop a Product Schedule from the Toolbox into the simulation.

From the Equipment > Product Schedule)

Note that if no destinations are defined then products will be assigned -1 as a destination.